The key role of pipe threading machine in oil and gas pipeline processing

In the oil and gas industry, efficient and reliable pipeline construction is crucial for ensuring the safety, stability, and long-term operation of infrastructure. One of the most essential tools in this process is the pipe threading machine , a device that enables precise thread cutting on steel pipes to ensure secure connections between segments. As the demand for faster, safer, and more cost-effective construction methods grows, the role of intelligent and automated electric pipe threadings becomes increasingly significant.

Among the companies leading this technological evolution is Hangzhou Xinabo Intelligent Electromechanical Technology Co., Ltd . Since its establishment, Xinabo has been dedicated to revolutionizing the field of thread processing through continuous innovation and high-quality engineering solutions. With over 12 years of research and development experience, the company has successfully launched nine generations of intelligent threading machines, each representing a major leap forward in automation, efficiency, and precision.

Why Threading Machines are Essential in Oil and Gas Pipelines

Pipelines in the oil and gas sector are typically made from large-diameter steel tubes that must be connected securely to prevent leaks, pressure loss, or structural failure. Traditional methods of connection—such as welding—are not only time-consuming and labor-intensive but also require highly skilled workers and pose potential safety risks. In contrast, threaded connections offer a faster, more standardized, and safer alternative when executed properly.

A high-performance threading machine ensures consistent thread quality across thousands of pipe joints, reducing the risk of mechanical failure and enhancing overall system integrity. This is particularly important in offshore platforms, refineries, and long-distance transmission pipelines where maintenance and repair are difficult and costly.

Founded by an expert with over 20 years of hands-on experience in pipeline construction, Hangzhou Xinabo recognized early on the limitations of traditional construction practices—namely, their inefficiency, high labor dependency, and associated costs. Motivated by these challenges, the company embarked on a mission to develop smarter, more reliable threading solutions.

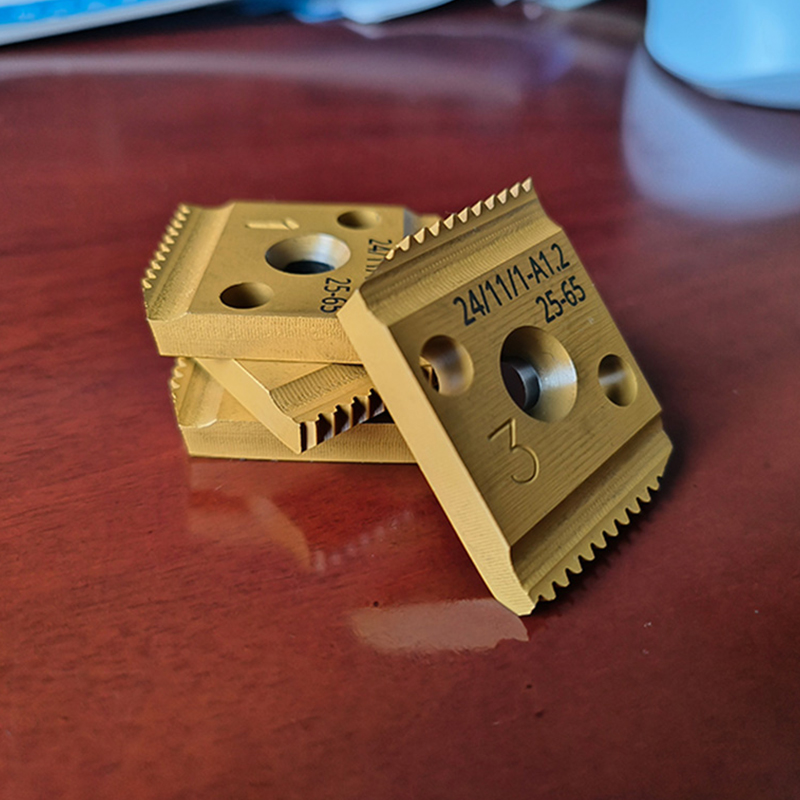

After more than a decade of R&D, Xinabo introduced a series of advanced intelligent threading machines that integrate automation, digital control, and real-time monitoring technologies. These machines significantly reduce manual labor requirements while improving threading accuracy and repeatability. Currently, the company holds 30 patents and has been honored with the title of "National High-tech Enterprise" , a testament to its innovative strength and industry leadership.

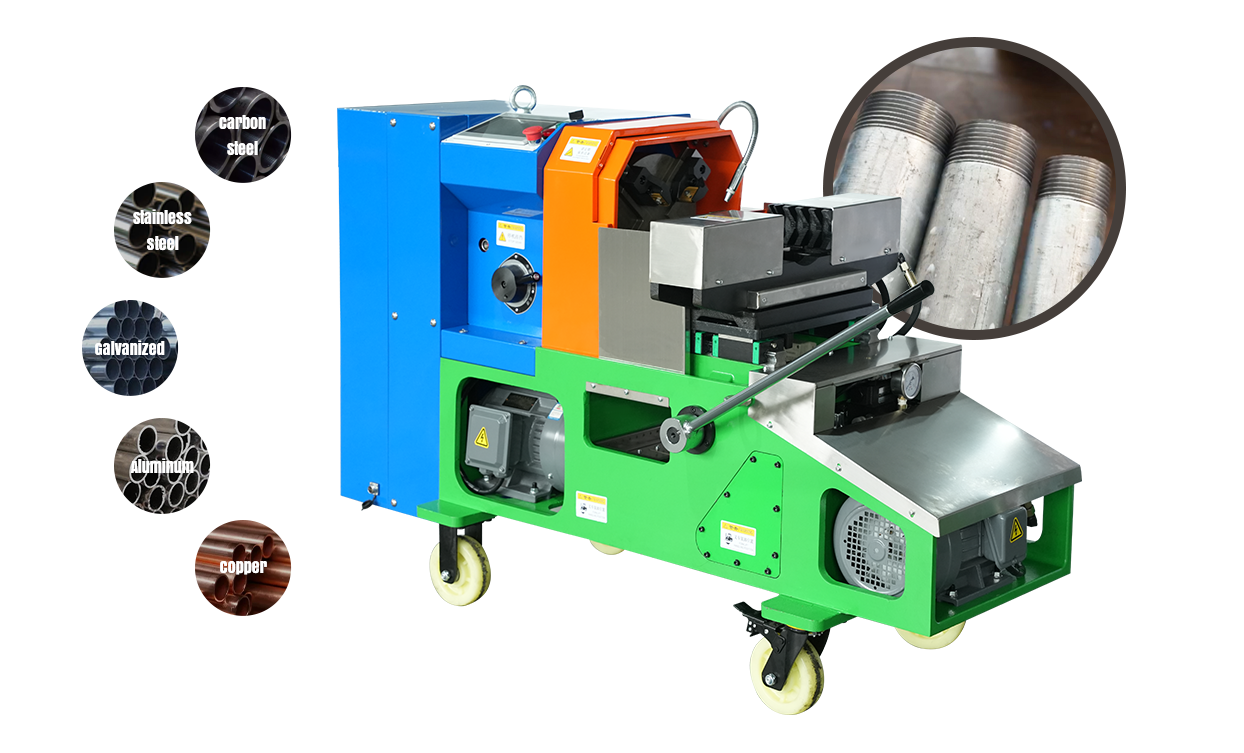

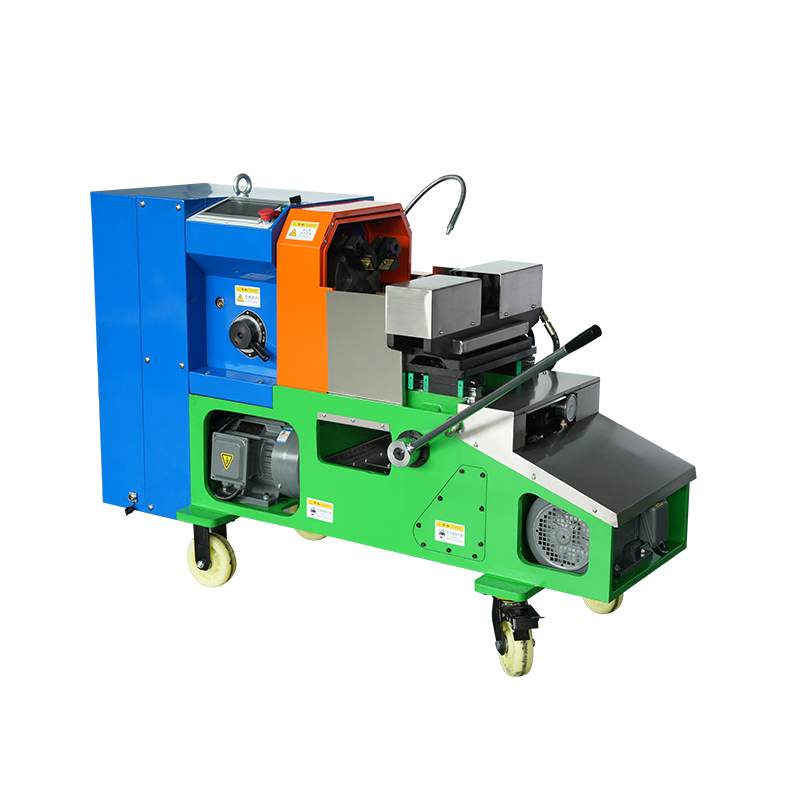

Xinabo’s threading machines are designed to meet the rigorous demands of modern pipeline projects. They support various pipe sizes and materials, including carbon steel, stainless steel, and alloy steel, making them suitable for both onshore and offshore applications. The integration of intelligent control systems allows operators to monitor key parameters such as cutting speed, depth, and torque, ensuring optimal performance and minimizing errors.

Moreover, these machines are equipped with automatic lubrication and cooling systems, which extend tool life and enhance machining efficiency. Their modular design also facilitates easy maintenance and adaptability to different working environments—an essential feature for remote or harsh conditions commonly found in oil and gas fields.

Applications Beyond Oil and Gas: Expanding Impact

While the oil and gas sector remains a core market for Xinabo's products, their intelligent threading machines have also gained widespread adoption in other industries, including fire protection engineering, building construction, and industrial piping systems. Customers appreciate the machines' high efficiency, stability, and user-friendly interface , which collectively contribute to reduced project timelines and lower operational costs.

The company’s customer-centric philosophy drives its commitment to continuous improvement and tailored service. Whether it's providing customized equipment configurations or offering technical training and after-sales support, Xinabo ensures that clients receive comprehensive solutions that align with their specific needs.

As global energy demand continues to rise and infrastructure development accelerates worldwide, the need for advanced pipe thread making machine technology will only grow. Hangzhou Xinabo Intelligent Electromechanical Technology Co., Ltd is well-positioned to lead this transformation by leveraging its deep technical expertise and relentless pursuit of innovation.

With a growing portfolio of patented technologies and a proven track record in delivering high-performance machinery, Xinabo is expanding its reach beyond China into international markets. The company welcomes inquiries from global partners who are seeking reliable, smart, and future-ready solutions for their pipeline construction and industrial processing needs.

The pipe threading equipment plays a pivotal role in the oil and gas pipeline industry by enabling fast, safe, and durable connections. Companies like Hangzhou Xinabo Intelligent Electromechanical Technology Co., Ltd are at the forefront of this technological advancement, offering intelligent, automated solutions that redefine productivity and reliability in modern pipeline construction. As the industry evolves, so too will the capabilities of these machines, driven by pioneers committed to shaping the future of global infrastructure.

English

English

Español

Español

عربى

عربى