Intelligent Pipe Twisting Machine's stable performance and operational advantages in complex environments

In the ever-evolving landscape of modern industrial manufacturing, efficiency, precision, and reliability have become the core demands of pipeline construction and engineering. Hangzhou Xinabo Intelligent Electromechanical Technology Co., Ltd has emerged as a pioneering force in this domain, offering cutting-edge intelligent pipe twisting machines that deliver exceptional performance even in the most complex environments.

Established with a clear mission to revolutionize traditional thread processing methods, Hangzhou Xinabo has grown into a leading company in the field of intelligent threading machine manufacturing. With over 12 years of dedicated research and development, the company has successfully launched nine generations of intelligent pipe twisting machines—each one a testament to its relentless pursuit of innovation and quality. Today, the company holds 30 patents and has been honored with the prestigious title of "National High-tech Enterprise," underscoring its technological leadership and industry influence.

The founder of Hangzhou Xinabo brings more than two decades of hands-on experience in pipeline construction, which laid the foundation for the company’s vision. Having witnessed firsthand the inefficiencies of conventional methods—such as high labor intensity, time-consuming processes, long project cycles, and elevated costs—the company set out to develop an intelligent alternative that could address these pain points comprehensively.

Traditional pipe threading often relies heavily on manual labor or outdated machinery, which not only limits productivity but also compromises consistency and safety. In contrast, Xinabo’s intelligent pipe twisting machines are engineered to operate autonomously, significantly reducing human intervention while enhancing accuracy and output. This shift from manual to intelligent automation marks a turning point in how industries approach pipeline processing today.

Stability in Complex Environments

One of the standout features of Xinabo’s Pipe Twisting Machines is their ability to maintain stable performance under challenging conditions. Whether it's extreme temperatures, fluctuating humidity levels, or demanding work sites with limited space, these machines are built to withstand environmental stressors without compromising operational efficiency.

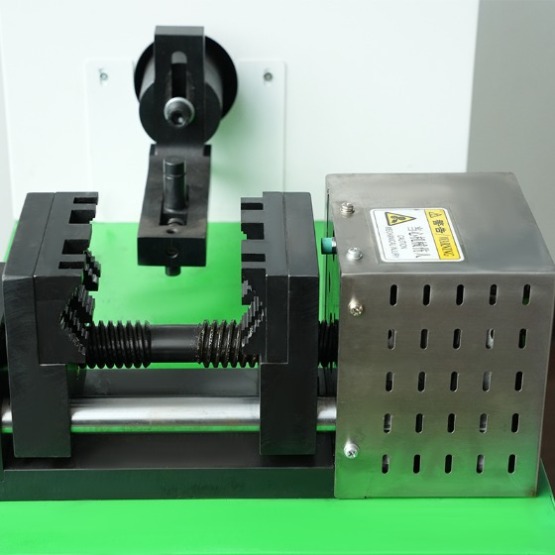

This stability is achieved through advanced sensor integration, real-time monitoring systems, and robust mechanical design. The machines utilize smart algorithms that adjust parameters dynamically based on feedback from the working environment, ensuring consistent torque control, precise threading depth, and uniform surface finish. Such adaptability is crucial in fields like fire protection engineering and large-scale construction projects, where even minor deviations can lead to costly rework or safety hazards.

Moreover, the equipment is designed with anti-vibration structures and reinforced frames to ensure durability and longevity, especially in harsh industrial settings. These enhancements allow the machines to perform continuously for extended periods without degradation in performance, making them ideal for both indoor and outdoor applications.

Operational Advantages: Efficiency, Intelligence, and Ease of Use

Beyond stability, Xinabo’s intelligent pipe twisting machines offer a host of operational advantages that make them indispensable tools in modern engineering:

High Efficiency : Thanks to automated feeding, clamping, and threading mechanisms, these machines can complete tasks at speeds far exceeding those of traditional methods. A single unit can replace multiple workers, significantly boosting productivity while lowering labor costs.

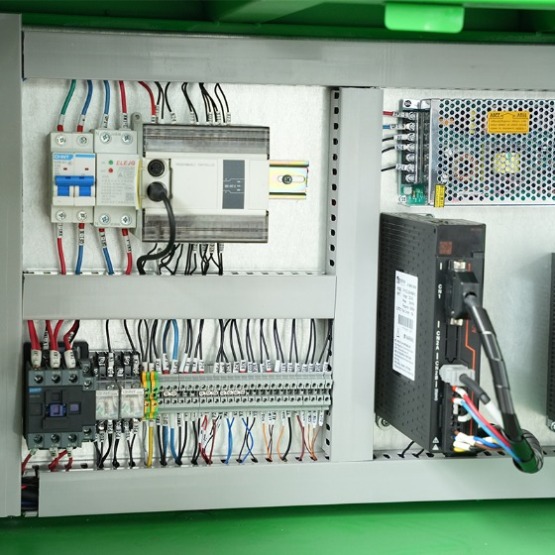

Smart Control Systems : Equipped with user-friendly touchscreens and programmable logic controllers (PLCs), operators can easily set and monitor key parameters such as rotation speed, pressure, and threading depth. Data logging and fault diagnostics further enhance maintenance efficiency and reduce downtime.

Energy Efficiency : Designed with energy conservation in mind, the machines incorporate optimized motor systems and low-power consumption components, aligning with global sustainability trends and reducing overall operational costs.

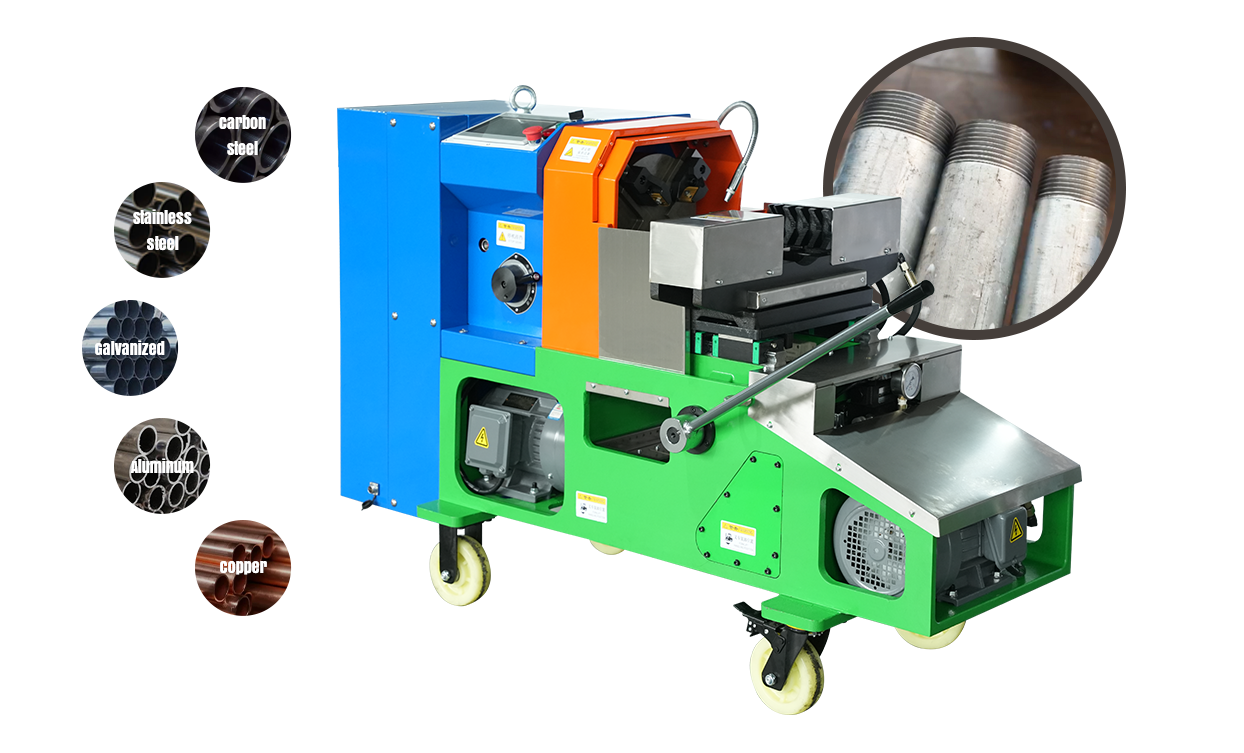

Versatility : The equipment supports a wide range of pipe diameters and materials, including steel, stainless steel, and PVC, making it suitable for diverse applications across industries such as construction, HVAC, water supply systems, and fire protection.

Safety Assurance : Integrated safety protocols prevent overheating, overloading, and improper operation, protecting both the machine and the operator. Emergency stop functions and protective covers ensure safe usage in crowded or hazardous environments.

Hangzhou Xinabo has always adhered to a customer-centric and market-oriented philosophy. Every product iteration is informed by extensive field testing and direct feedback from clients, ensuring that the machines meet real-world needs. As a result, Xinabo’s solutions are widely adopted in major infrastructure projects, earning deep trust among engineers, contractors, and facility managers.

The company’s commitment to after-sales service further strengthens customer confidence. From installation guidance to technical support and regular maintenance, Xinabo ensures seamless integration and sustained performance of its machines throughout their lifecycle.

Hangzhou Xinabo Intelligent Electromechanical Technology Co., Ltd has redefined the standards of pipe twisting technology through its intelligent, durable, and highly efficient machines. By combining advanced engineering with practical usability, the company continues to empower industries worldwide with solutions that thrive in complexity and deliver unmatched value.

As demand for smarter and more resilient industrial equipment grows, Xinabo remains at the forefront, driving progress and setting new benchmarks in intelligent electromechanical innovation. For companies seeking reliable, high-performance pipe twisting solutions, Xinabo stands as a trusted partner committed to excellence and continuous improvement.

English

English

Español

Español

عربى

عربى