Analysis of the efficient and energy-saving application of Frequency Conversion Metal Cold Cutting Saw in modern industrial cutting

In the rapidly evolving industrial manufacturing sector, efficiency and energy conservation have become key indicators for evaluating machinery performance. Among various cutting technologies, frequency conversion metal cold cutting saws have emerged as a highly efficient and environmentally friendly solution. This article explores the working principles, advantages, and practical applications of frequency conversion cold cutting saws, with a focus on their role in modern industrial processing, particularly through the lens of Hangzhou Xinabo Intelligent Electromechanical Technology Co., Ltd — a leader in intelligent threading machine development that has also expanded its innovation into advanced cutting equipment.

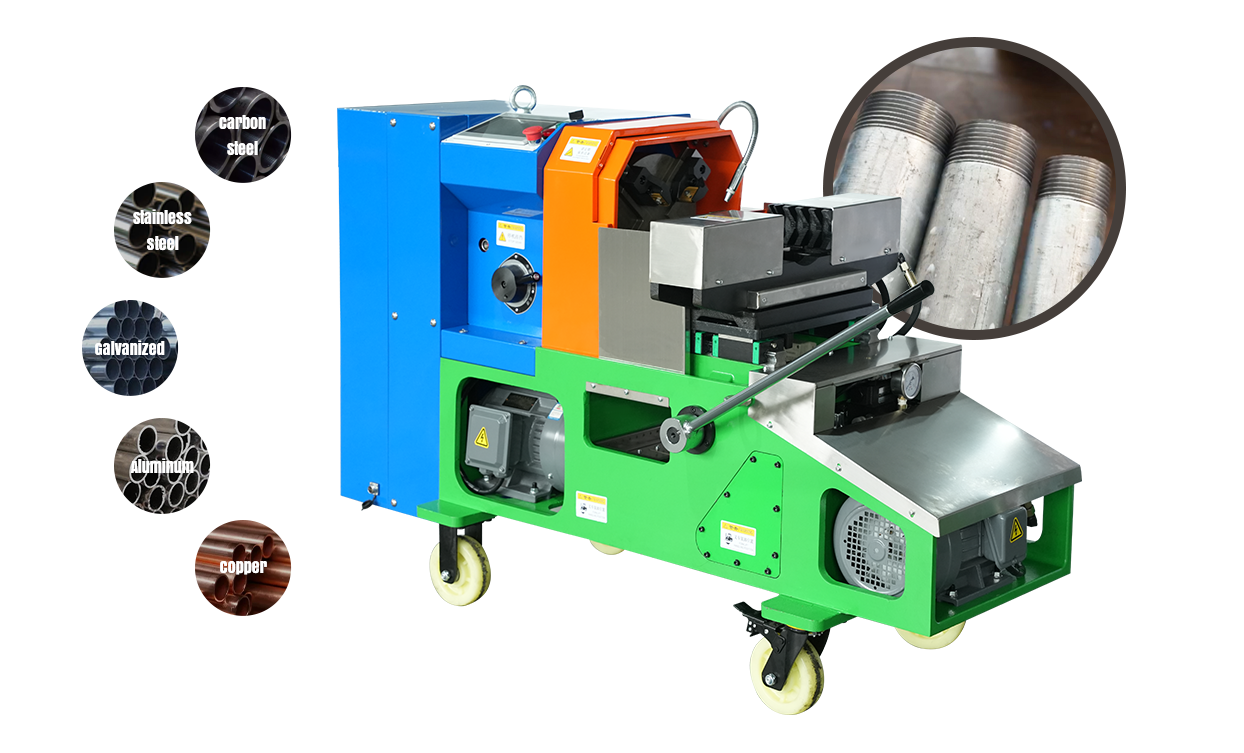

A Metal Cold Cutting Saw is a type of precision cutting equipment that utilizes variable frequency drive (VFD) technology to control motor speed and torque. Unlike traditional hot cutting methods such as plasma or flame cutting, cold cutting does not generate high temperatures, thus avoiding material deformation, oxidation, and harmful emissions. The use of VFD allows real-time adjustment of cutting parameters based on material thickness and hardness, optimizing both power consumption and cutting efficiency.

This technology aligns perfectly with current trends in green manufacturing and Industry 4.0 automation, where energy savings, precision, and environmental sustainability are prioritized.

Advantages of Frequency Conversion Cold Cutting Saws

Energy Efficiency :

By adjusting motor frequency according to workload, frequency conversion systems significantly reduce idle power consumption. Compared to fixed-speed motors, VFD-equipped machines can cut energy usage by up to 30%, contributing to lower operational costs and carbon footprints.

Precision and Stability :

The adjustable speed and torque control ensure consistent cutting quality across different materials. This is especially crucial in industries like construction and fire protection engineering, where dimensional accuracy and surface finish are critical.

Extended Equipment Lifespan :

Reduced mechanical stress due to soft starts and stops prolongs the life of cutting blades and motors, minimizing maintenance downtime and replacement costs.

Environmental Friendliness :

Cold cutting eliminates the need for cooling agents or high-temperature processes, reducing hazardous waste and air pollution. This makes it an ideal choice for companies aiming to meet international environmental standards.

Integration with Smart Manufacturing :

Many modern frequency conversion saws come equipped with PLC controls and IoT interfaces, enabling remote monitoring and data collection. This integration supports predictive maintenance and process optimization in smart factories.

Hangzhou Xinabo: A Pioneer in Intelligent Industrial Solutions

Hangzhou Xinabo Intelligent Electromechanical Technology Co., Ltd has been at the forefront of developing innovative solutions for industrial machining since its inception. With over 12 years of dedicated R&D , the company has launched nine generations of intelligent threading machines and holds 30 patents , earning the prestigious title of “National High-tech Enterprise ”.

While best known for its intelligent threading machines, Hangzhou Xinabo has extended its expertise in automation and energy-efficient design to the field of industrial cutting. Drawing from its deep understanding of pipeline construction challenges — including time-consuming processes, labor intensity, and high costs — the company applies similar technological principles to optimize cold cutting equipment.

By integrating frequency conversion technology , Xinabo ensures that its cutting machines deliver superior performance while maintaining low energy consumption and high durability. This approach reflects the company’s commitment to providing customers with efficient, intelligent, and stable thread processing and cutting solutions , catering to sectors such as fire protection engineering, construction engineering, and more.

Practical Applications in Modern Industries

The application of frequency conversion cold cutting saws is particularly prominent in the following areas:

Construction Engineering : Precise cutting of steel pipes and structural materials ensures smooth assembly and reduces rework.

Fire Protection Systems : Accurate cuts in piping help maintain system integrity and pressure resistance.

Mechanical Manufacturing : High-efficiency cutting of raw materials improves production throughput and reduces scrap rates.

Infrastructure Projects : From bridges to tunnels, cold cutting enhances safety and workability on large-scale sites.

In all these fields, Hangzhou Xinabo's equipment has gained widespread recognition for its reliability, user-friendly interface, and cost-effectiveness.

As industries worldwide strive toward sustainable and intelligent development, the adoption of Cold Saw for metal represents a significant step forward. These machines offer a compelling combination of energy efficiency, cutting precision, and environmental benefits — qualities that are increasingly indispensable in modern manufacturing.

Hangzhou Xinabo Intelligent Electromechanical Technology Co., Ltd exemplifies how continuous innovation and customer-centric approaches can lead to the successful integration of advanced technologies like frequency conversion into industrial cutting. As the company continues to push boundaries in intelligent electromechanical solutions, it sets a benchmark for others in the pursuit of smarter, greener, and more efficient industrial practices.

Whether you are involved in construction, fire protection, or general manufacturing, embracing frequency conversion cold cutting technology is not just a trend — it's a strategic necessity for future growth. Welcome to inquire about Hangzhou Xinabo's range of intelligent cutting and threading solutions and discover how your business can benefit from next-generation industrial innovation.

![]() 130mm

130mm ![]() 125mmx125mm

125mmx125mm ![]() 110mm×170mm

110mm×170mm

English

English

Español

Español

عربى

عربى