1. Automatically identify the pipe diameter

2. Automatic tool adjustment and setting

3. Thread diameters from 15mm to 100mm

4. Threading time as low as 4s(15-25mm)

5. Scope of application: British thread, American thread, Metric thread, customized non-standard thread

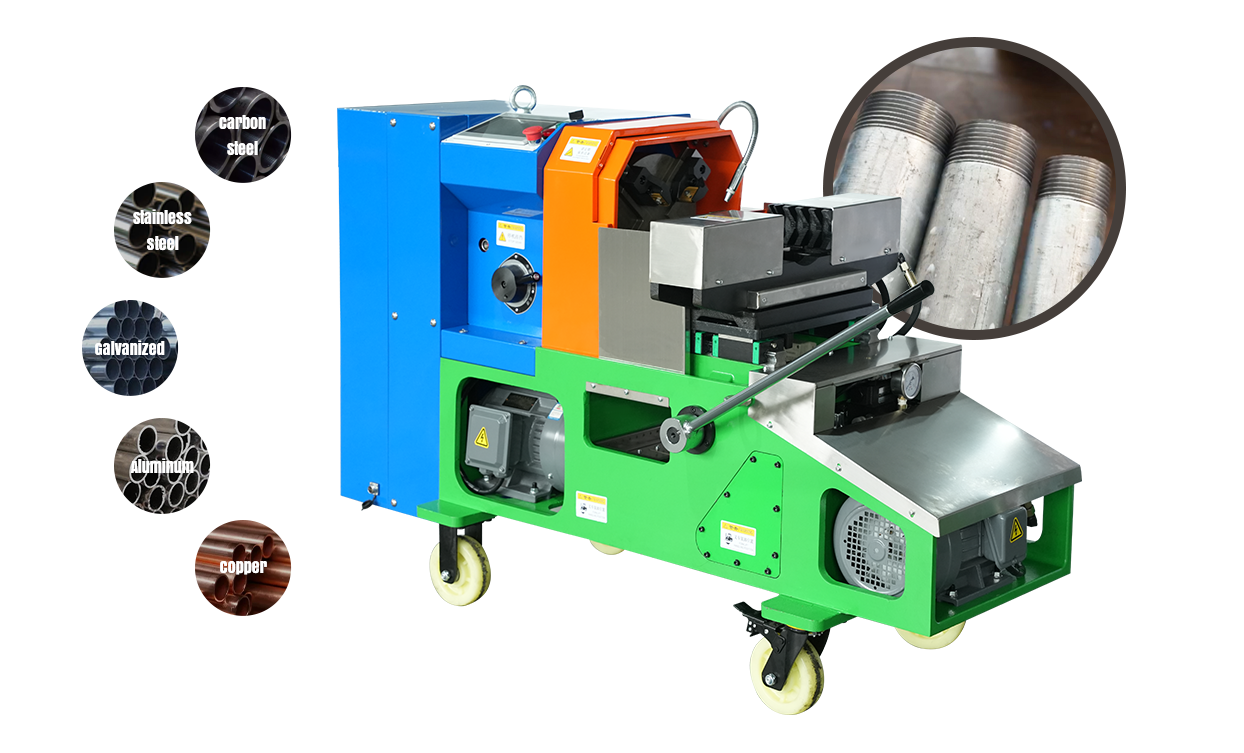

6. Applicable materials: carbon steel pipe, galvanized pipe, stainless steel pipe, aluminum pipe, and copper pipe

7. 1500-2000 threads very day (8hours), save labor costs, high efficient 10 times more than traditional threading machine

8. Comply with international standards, low Consumption

9. Higher thread quality and precision

10. Easy to operate, Easy to carry

English

English

Español

Español

عربى

عربى