What Is a Frequency Conversion Metal Cold Cutting Saw?

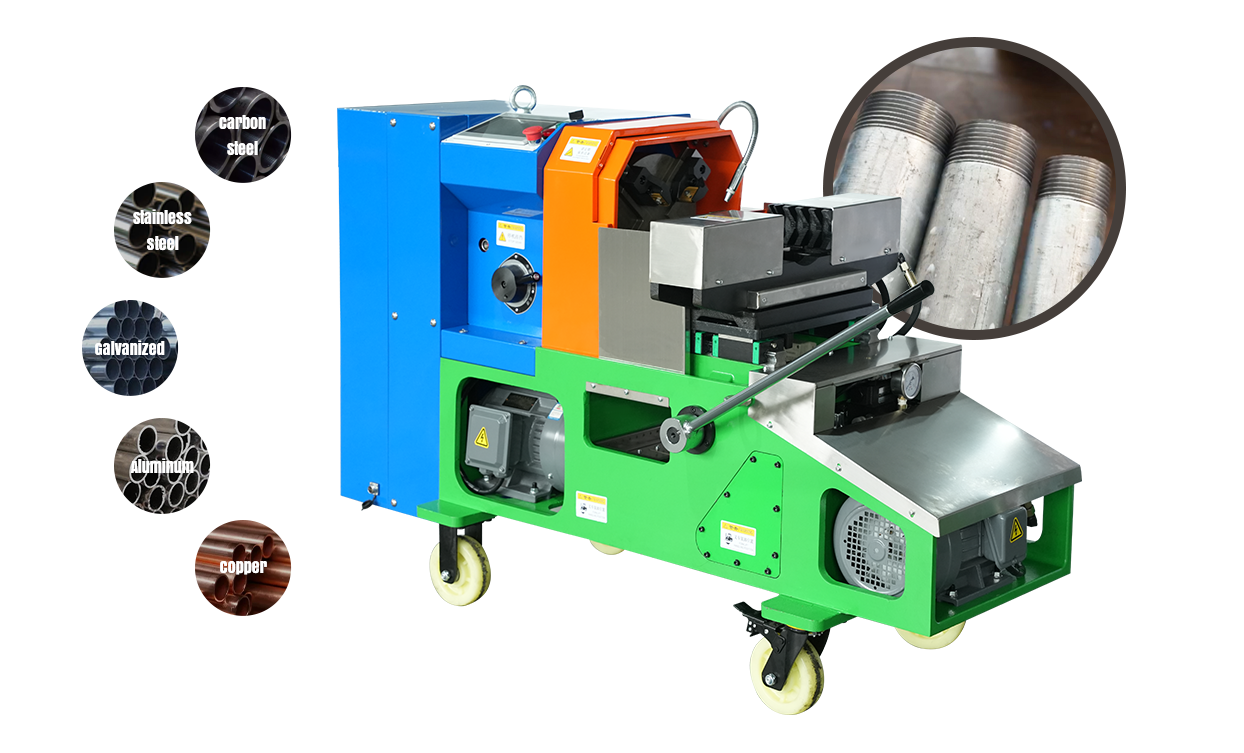

A frequency conversion metal cold cutting saw is an advanced cutting machine designed for precision metalworking. Unlike traditional saws that generate excessive heat, this saw uses a frequency converter to control motor speed, ensuring a clean, burr-free cut without thermal distortion. It's ideal for cutting stainless steel, aluminum, copper, and other metals with high accuracy.

How Does a Frequency Conversion Cold Cutting Saw Work?

The key component of this saw is the frequency converter, which adjusts the motor's rotational speed based on material thickness and hardness. This ensures:

- Reduced Heat Generation: Prevents material warping.

- Precision Cutting: Delivers smooth, accurate cuts.

- Energy Efficiency: Optimizes power consumption.

The cold cutting process avoids high temperatures, preserving the metal's structural integrity.

Key Benefits of Using a Frequency Conversion Cold Cutting Saw

1. High Precision & Clean Cuts

Traditional saws often leave rough edges, requiring additional finishing. A cold cutting saw produces smooth cuts with minimal burrs, reducing post-processing time.

2. No Heat-Affected Zones (HAZ)

Since the saw operates at lower temperatures, it eliminates heat-induced deformations, making it perfect for sensitive metals like titanium and aerospace alloys.

3. Extended Blade Life

The controlled speed reduces friction, significantly increasing the lifespan of cutting blades compared to abrasive saws.

4. Energy Savings

The frequency converter optimizes power usage, lowering operational costs by up to 30% compared to conventional saws.

Applications of Frequency Conversion Cold Cutting Saws

These saws are widely used in industries requiring high precision and material integrity:

- Metal Fabrication: Cutting pipes, tubes, and structural steel.

- Aerospace: Precision cutting of high-strength alloys.

- Automotive: Manufacturing exhaust systems and chassis components.

- Oil & Gas: Pipeline and drilling equipment maintenance.

Choosing the Right Cold Cutting Saw

When selecting a frequency conversion metal saw, consider:

- Material Type: Ensure compatibility with stainless steel, aluminum, etc.

- Cutting Capacity: Check maximum diameter/thickness.

- Blade Type: Carbide-tipped blades last longer.

- Automation Features: CNC integration for repeatable cuts.

Maintenance Tips for Longevity

To keep your saw in optimal condition:

- Regularly lubricate moving parts.

- Inspect blades for wear and replace as needed.

- Clean metal chips to prevent buildup.

- Calibrate the frequency converter periodically.

Why Upgrade to a Frequency Conversion Saw?

If you're still using an abrasive or traditional bandsaw, upgrading to a cold cutting saw with frequency conversion offers:

- Faster production cycles.

- Lower energy costs.

- Improved cut quality.

- Reduced material waste.

It's a long-term investment that enhances efficiency and product quality.

Top Brands & Models to Consider

Some reputable manufacturers include:

- Everising Machine Tools – Known for durable industrial saws.

- Behringer – Offers high-precision cold cutting systems.

- Kasto – Specializes in automated metal cutting solutions.

Look for models with variable frequency drive (VFD) for better control.

Conclusion

A frequency conversion metal cold cutting saw is a game-changer for metalworking, delivering precision, efficiency, and cost savings. Whether you're in fabrication, aerospace, or automotive industries, this technology ensures superior cuts without compromising material properties. Investing in the right saw can streamline operations and improve product quality significantly.

English

English

Español

Español

عربى

عربى