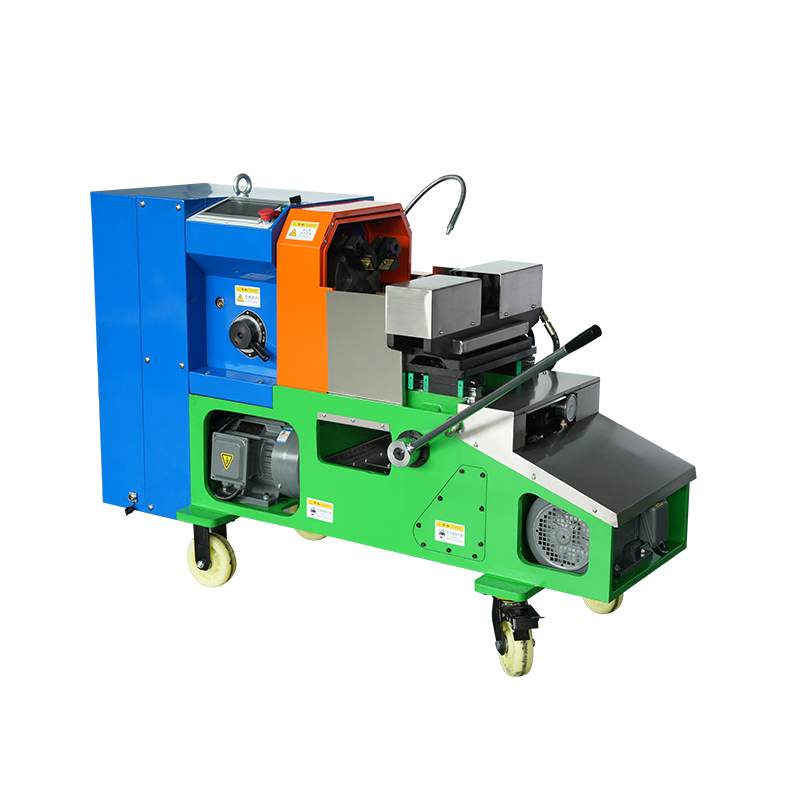

Intelligent Threading Machine

1. Automatically identify the pipe diameter 2. Automatic tool adjustment and setting 3. Thread diameters from 15mm to 100mm 4. Threading time as lo...

See DetailsWhen it comes to pipe fabrication, one of the most critical factors is the quality and precision of the threads. Thread pitch and depth are not just technical specifications—they determine the reliability, safety, and efficiency of piping systems in industries ranging from plumbing to oil and gas. A Pipe Thread Making Machine plays a central role in achieving these precise threads, but how precise are they really?

Before delving into the capabilities of a Pipe Thread Making Machine, it is important to understand what thread pitch and depth mean.

Thread Pitch refers to the distance between two consecutive threads on a pipe. Maintaining a consistent pitch is crucial because it ensures the pipe can be properly connected with fittings and other threaded components. Even slight variations in pitch can lead to leaks or weak joints.

Thread Depth is the distance from the crest of the thread to its root. Correct thread depth is essential for strength and sealing integrity. If the thread is too shallow, the connection may fail under pressure. If too deep, the pipe material could be weakened or damaged.

Together, pitch and depth define the profile of a thread. For critical applications, such as high-pressure gas or water pipelines, achieving precise pitch and depth is essential to prevent failures and maintain safety standards.

A Pipe Thread Making Machine is designed to cut threads on the ends of pipes with high precision. The process typically involves the following components and steps:

Pipe Holding and Clamping: The pipe is secured in the machine to prevent any movement during threading. Stability is critical for thread accuracy.

Cutting Dies: The machine uses dies specifically shaped for the desired thread profile. These dies move along the pipe, cutting the threads consistently.

Rotation and Feed Control: Modern machines control both the rotational speed of the pipe and the feed rate of the cutting dies. Consistent feed ensures even thread pitch and uniform depth.

Lubrication: Proper lubrication reduces heat and wear, helping maintain precise dimensions over many cycles.

Inspection and Measurement: Some advanced machines include digital readouts or gauges to measure thread pitch and depth in real time, further improving accuracy.

Even the best Pipe Thread Making Machine cannot achieve perfect threads if other factors are neglected. Some key influences include:

Different pipe materials respond differently to threading. Soft metals like aluminum may deform easily, affecting thread depth, while harder materials like stainless steel require more force and may wear out dies faster. Choosing the right die and machine settings for the material is essential.

Regular calibration of the Pipe Thread Making Machine ensures that the cutting dies move accurately along the pipe. Misalignment or wear can cause uneven pitch or inconsistent depth.

Even automatic machines require skilled operators. Proper loading, correct die selection, and monitoring the cutting process all impact the final thread quality.

Dull or worn dies produce threads that are inconsistent in depth and pitch. Regular maintenance and timely replacement of dies are necessary to maintain precision.

Too fast a feed rate can lead to shallow or uneven threads, while too slow a feed can create excessive friction and heat, which may distort the thread. Optimizing these parameters is crucial.

After threading, it is important to verify the pitch and depth. Standard methods include:

Regular inspection is particularly important in industries like plumbing, petrochemical, and aerospace, where thread failure can have serious consequences.

The precision of a Pipe Thread Making Machine varies depending on the type, brand, and operational conditions. Generally:

These tolerances are sufficient for most industrial applications, including high-pressure pipelines and threaded fittings.

To ensure consistent thread quality, consider the following practices:

By adhering to these practices, a Pipe Thread Making Machine can deliver high-quality threads reliably over long periods.

The precision of thread pitch and depth on a Pipe Thread Making Machine is influenced by multiple factors, including machine quality, operator skill, die condition, and pipe material. When properly maintained and operated, these machines can achieve highly consistent threads suitable for demanding applications. Accurate threads are vital for ensuring leak-proof, strong, and reliable piping systems.

While no machine is entirely immune to errors, understanding the factors that affect thread quality and implementing best practices can help maintain precision, protect safety, and improve overall efficiency in pipe fabrication operations.