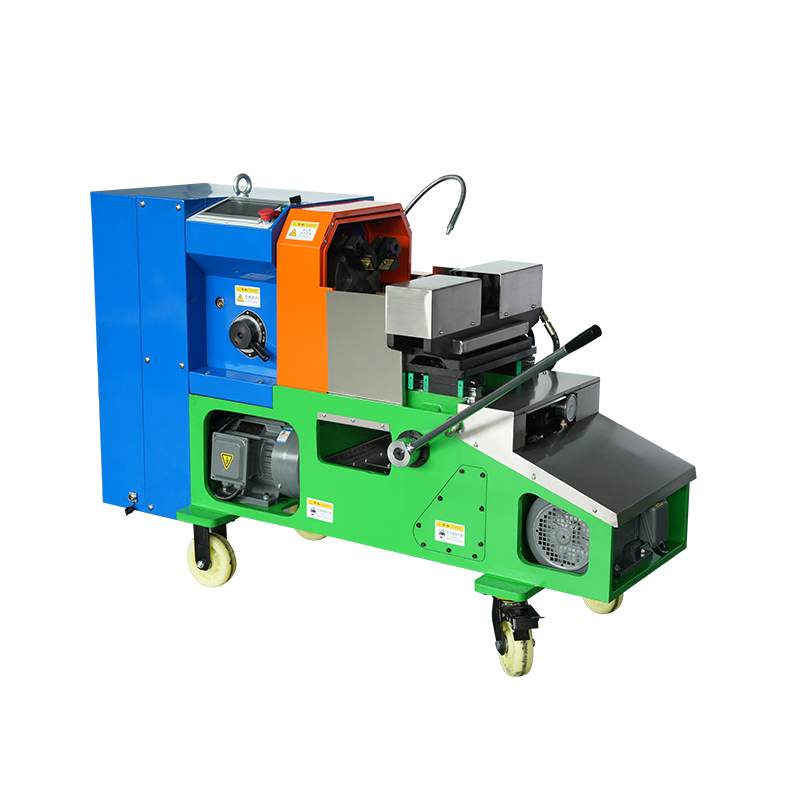

Intelligent Threading Machine

1. Automatically identify the pipe diameter 2. Automatic tool adjustment and setting 3. Thread diameters from 15mm to 100mm 4. Threading time as lo...

See DetailsThe manufacturing industry has seen significant advancements in automation and precision engineering, with intelligent threading machine playing a crucial role. These machines enhance efficiency, reduce human error, and improve the quality of threaded components. Whether used in automotive, aerospace, or general fabrication, intelligent threading machines are transforming production lines.

This article explores the key features, benefits, and applications of intelligent threading machines while providing practical insights for manufacturers looking to optimize their operations.

An intelligent threading machine is a CNC (Computer Numerical Control) or PLC (Programmable Logic Controller)-based device designed to create precise internal or external threads on workpieces. Unlike traditional manual threading, these machines automate the process, ensuring consistency and reducing production time.

| Feature | Description |

| Automated Operation | Reduces manual intervention with programmable settings for different thread types. |

| High Precision | Ensures tight tolerances, improving thread quality and reducing defects. |

| Multi-Axis Control | Allows complex threading operations, including tapered and multi-start threads. |

| Real-Time Monitoring | Sensors detect tool wear and deviations, enabling automatic adjustments. |

| Quick Tool Change | Modular designs allow fast switching between threading tools. |

| Energy Efficiency | Optimizes power usage, lowering operational costs. |

Intelligent threading machines significantly reduce cycle times compared to manual threading. Automated loading and unloading systems further enhance throughput, making them ideal for high-volume production.

Human errors in manual threading can lead to costly rework. Intelligent machines ensure uniformity across thousands of parts, maintaining compliance with industry standards like ISO and ANSI.

Automation minimizes the need for skilled operators, allowing businesses to allocate human resources to more complex tasks.

Advanced cooling systems and adaptive toolpath strategies reduce wear and tear, extending the lifespan of threading inserts and dies.

These machines can produce various thread forms, including:

Intelligent threading machines are used across multiple industries due to their versatility and precision.

Threaded fasteners, engine components, and transmission parts require high precision to ensure safety and performance.

Aerospace-grade threads must withstand extreme conditions, making automated threading essential for reliability.

Pipe threading for drilling equipment and valves demands durability and leak-proof connections.

Surgical instruments and implants require micro-threading with ultra-fine tolerances.

From bolts to hydraulic fittings, threaded components are fundamental in machinery and consumer goods.

Selecting the best threading machine depends on several factors:

Look for machines with:

Consider machines with:

The evolution of intelligent threading machines is driven by Industry 4.0 and smart manufacturing trends.

Machine learning algorithms can predict tool wear and optimize cutting parameters in real time.

Smart threading machines can transmit performance data to centralized systems for predictive maintenance.

Combining threading with milling or turning in a single setup reduces handling time.

Energy-efficient designs and recyclable cutting fluids align with eco-friendly production goals.

Intelligent threading machines are indispensable in modern manufacturing, offering unmatched precision, efficiency, and cost savings. By understanding their features, benefits, and selection criteria, manufacturers can make informed decisions to enhance their production capabilities.

As threading technology continues to evolve, businesses that adopt these advanced solutions will stay competitive in an increasingly automated industrial landscape.