Core Operational Philosophy: Human Skill vs. Automated Precision

The fundamental distinction lies in the source of control and decision-making. A manual pipe twisting machine is entirely dependent on the operator's skill, physical strength, and judgment. The worker manually clamps the pipe, often uses a lever or wheel to initiate the twist, and relies on visual markers or measuring tools to gauge the angle or pitch, stopping when it appears correct. Conversely, an Intelligent Pipe Twisting Machine is governed by a programmable logic controller (PLC) or CNC system. The operator inputs the desired parameters—twist angle, pitch, speed, number of rotations—into a human-machine interface (HMI) screen. The machine's servo motors and sensors then execute the program with precise, repeatable movements, removing human variability from the core twisting process.

Precision, Consistency, and Repeatability

This difference in control leads to a dramatic gap in output quality. Manual machines are prone to inherent inconsistencies. Factors like operator fatigue, varying force application, and subjective visual checks result in subtle differences from one piece to the next. This can cause significant issues in assembly or final product performance. Intelligent machines eliminate this variability. Once programmed, they produce hundreds or thousands of identical twists with tolerances often within a fraction of a degree. This level of repeatability is critical for modern manufacturing where components must be interchangeable and assemblies automated.

Key Quality Metrics Comparison

The following table illustrates the typical differences in critical output metrics:

| Metric | Manual Machine | Intelligent Machine |

| Angular Accuracy | ± 2° to 5° (highly variable) | ± 0.1° to 0.5° (consistent) |

| Twist Repeatability | Low; differs between operators and batches | Extremely High; identical across all production runs |

| Surface Protection | High risk of tool marks, scratches from manual handling | Programmable pressure control minimizes surface damage |

| Cycle Time Consistency | Varies with operator speed and focus | Fixed and optimized, leading to predictable throughput |

Production Efficiency and Throughput

The impact on production speed and labor utilization is profound. A manual machine is labor-intensive and slow, with speed limited by human physical capability. Complex twists require multiple steps and measurements. An Intelligent Pipe Twisting Machine operates at a constant, optimized speed, often performing complex twists in a single, rapid cycle. It enables one operator to manage multiple machines or perform other value-added tasks simultaneously. Furthermore, intelligent machines often feature automatic tooling changes and integration with upstream/downstream automation (like robotic arms for loading/unloading), creating a continuous production cell that dramatically increases overall equipment effectiveness (OEE).

Complexity of Tasks and Flexibility

While manual machines are limited to simple, standard twists, intelligent machines unlock complex geometries and advanced functionalities.

- Complex Programming: They can execute variable-pitch twists, S-shaped twists, or combinations of bend-and-twist in one setup, which is virtually impossible to achieve consistently by hand.

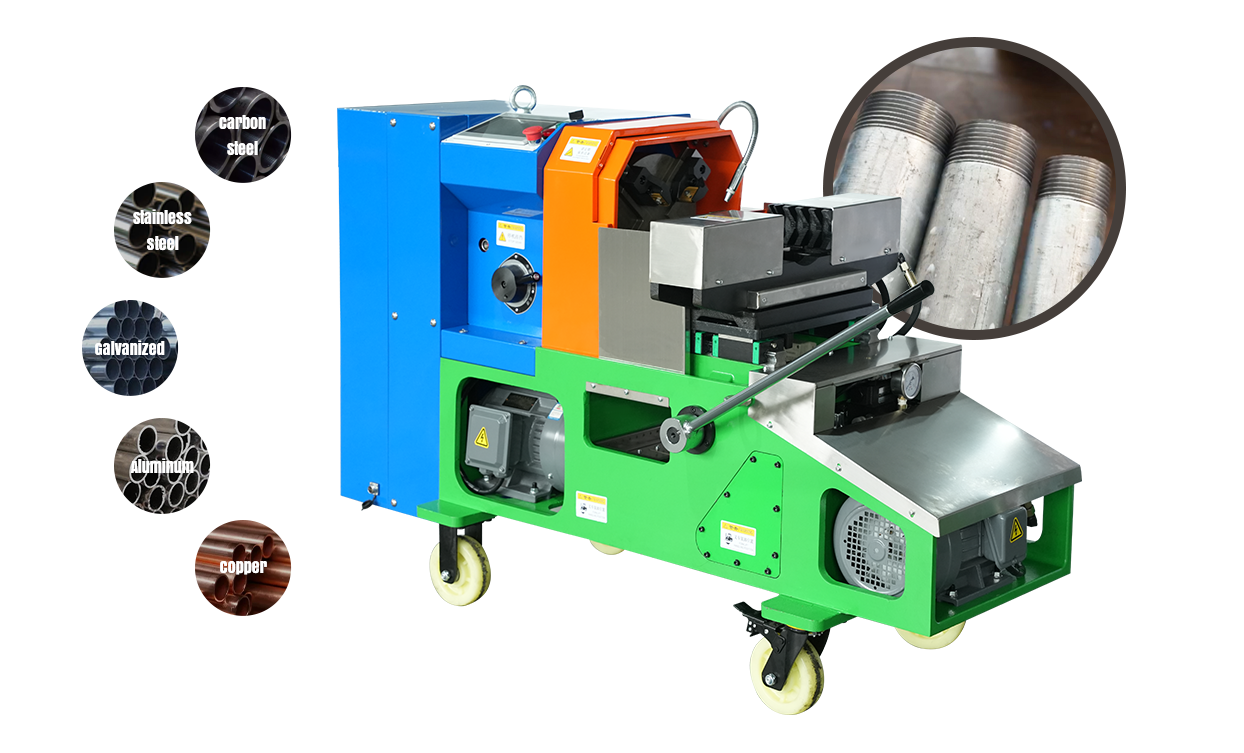

- Material Adaptability: With programmable torque and speed curves, the same intelligent machine can gently twist soft copper for HVAC coils and then switch to a high-torque program for stainless steel, all by loading a different recipe.

- Data and Traceability: Intelligent machines can log production data (counts, error codes, force monitoring) for each piece, aiding in quality traceability and process optimization.

Setup Time, Changeover, and Skill Requirements

For a manual machine, setup may involve physical adjustments of stops and jigs, which is time-consuming and requires experienced intuition. Changeover to a different product is slow. For an intelligent machine, setup is digital. Changeover for a new pipe diameter or twist design primarily involves calling up a pre-saved program and possibly changing tooling, which can be done in minutes. Crucially, the skill requirement shifts. The manual machine demands a highly skilled craftsperson. The intelligent machine requires an operator with basic mechanical understanding and the ability to navigate a digital interface, perform basic programming, and understand error messages—a different, more technical skillset.

Cost and Return on Investment Analysis

The choice is ultimately a financial and strategic calculation.

- Manual Machine: Lower initial capital investment. Lower ongoing maintenance complexity. Higher long-term variable costs due to labor intensity, slower throughput, scrap from errors, and quality inconsistencies.

- Intelligent Machine: Significantly higher upfront cost. Requires investment in training and potentially infrastructure. Delivers lower per-part cost at medium to high volumes through labor savings, material savings, and vastly higher throughput. Justification is based on production volume, quality requirements, and the strategic need for manufacturing agility.

Maintenance and Reliability Considerations

Manual machines, with their simpler mechanical design (bearings, gears, levers), are often easier for in-house maintenance staff to repair with common tools. Intelligent machines add layers of complexity: servo motors, encoders, PLCs, touch screens, and sophisticated software. Maintenance requires diagnostic skills for both mechanical and electronic systems, and reliance on specialized technicians or the supplier for complex issues. However, their built-in diagnostics and sensors can also provide predictive maintenance alerts, preventing unexpected downtime.

Ideal Application Scenarios

The decision is not about which is universally better, but which is appropriate for the context.

- Choose a Manual Machine for: Prototyping, very low-volume or job-shop work, workshops with budget constraints, or twisting very large, custom one-off pieces where programming time outweighs benefit.

- Choose an Intelligent Pipe Twisting Machine for: Repetitive batch production, medium to high-volume manufacturing, applications demanding tight tolerances and perfect consistency, complex twist geometries, and environments aiming for Industry 4.0 integration and data-driven production.

English

English

Español

Español

عربى

عربى